Basic Facts

The Institute of Forming Equipment and Automation, Tsinghua University, affiliated to the Department of Mechanical Engineering, is home to the Key Laboratory for Advanced Materials Processing Technology, MoE, and Beijing Key Laboratory of Biofabrication and Rapid Prototyping Technology. Among the current faculty members, six are professors, 13 are associate professors and four are assistant professors. In addition, Researcher Wang Guoqing, deputy director of China Academy of Launch Vehicle Technology, serves as an adjunct professor, and Feng Zhili, a senior researcher at the Oak Ridge National Laboratory in the United States, is engaged as a visiting professor.

Research Directions

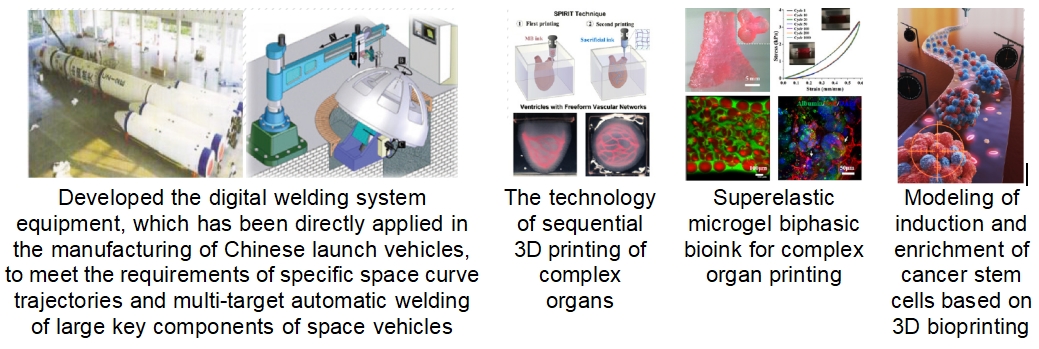

Major equipment forming:Welding technology of key components of nuclear power and thermal power energy equipment; theory and technology of large forging manufacturing; research on prestressed steel wire winding technology and its application in the manufacturing of heavy forging equipment.

Intelligent manufacturing:Special robotic technology and automation equipment for forming process; multi-sensor information fusion and optical-mechanical-electrical integration technology systems; digital welding equipment; advanced non-destructive testing technology systems.

Biofabrication:3D cell-controlled assembling technology; Tissue on Chip; biofabrication processes and equipment; research on tissue engineering technology.

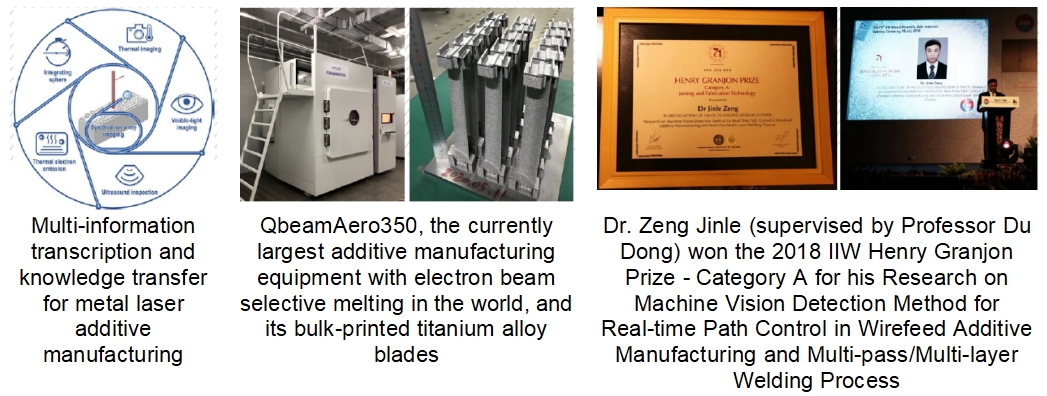

Additive manufacturing: Sintering forming process and equipment for selective sections of electron beams; laser micro-deposition three-dimensional metal molding; desktop three-dimensional printing forming equipment.

Research Achievements

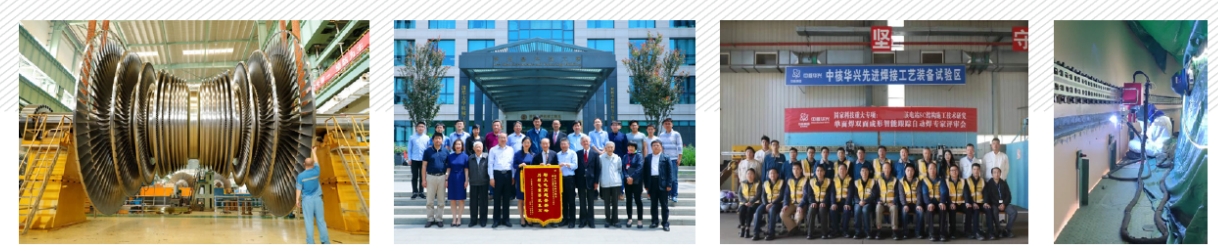

Fundamental researches and engineering applications were carried out in response to the development of science and technology and the needs of social and economic construction, involving such fields as heavy processing equipment, laser processing, additive manufacturing, biofabrication, aerospace equipment manufacturing, energy equipment manufacturing, robotics, advanced welding and connection, forming of large-scale casting and forging, non-destructive testing, etc. Before the establishment of the institute, the research group led by Academician Pan Jiluan won the first prize of the State Technological Invention Award for the new arc control method; and the researcher group led by Professor Yan Yongnian won the second and third prizes of the State Science and Technology Advancement Award for CIMS application engineering and prestressed winding hydraulic press technology respectively. In recent years, the faculty members of the institute won the second prizes of the State Science and Technology Advancement Award for the Colored Science and Technology Encyclopedia and the application of acoustic emission detection technology successively; led the design of the 360MN ferrous metal vertical extrusion press unit, which has been put into production, broken the blockade by foreign technology, and achieved the localization of large-diameter thick-walled seamless steel pipes, thus awarded the second prize of the State Science and Technology Advancement Award in 2015; applied bioprinting technology in clinical and critical treatment of obstetrics and gynecology to achieve outstanding results, thus winning the second prize of the State Science and Technology Advancement Award and the first prize of the Military Science and Technology Progress Award; presided over the design of China's first 400MN heavy-duty aviation die forging hydraulic press, to realize the independent development and production of large-scale aviation precision die forgings; presided over the formulation of technical standards for large-scale castings and forgings and thick steel plates, which provided technical support for the successful manufacturing of forgings for the Three Gorges Project, such as mirror plates for hydraulic turbines, and 1-million kW nuclear power main pipes; developed the CNC welding system equipment for large key components of space launch vehicles, which has been applied in the production and manufacturing of launch vehicles; conducted fruitful researches on the welding manufacturing technology of low-pressure rotors for 1-million kW nuclear power steam turbines and dissimilar metal rotors for advanced ultra-supercritical thermal power steam turbines; realized important progress in basic theoretical research on the origin and boundary of pore defects in the field of metal laser additive manufacturing (Science 370, 1080-1086 (2020)); developed electron beam selective melting (EBSM) additive manufacturing equipment, which has been industrialized, turning China into the second country capable of producing this equipment; and have made original achievements in scientific researches in the fields of biomedical model manufacturing, bioprosthesis manufacturing, tissue engineering scaffold manufacturing, and living body manufacturing, as the base for the Biomanufacturing Engineering Branch of the Chinese Mechanical Engineering Society, and the Advanced Biomaterials Manufacturing Branch of the Chinese Society for Biomaterials.

In terms of basic research, the research on the key mechanisms of metal laser additive manufacturing stands for an internationally cutting-edge level. By re-examining the laser melting model, the institute provided guiding principles and new research directions for the additive manufacturing of metal laser powder bed fusion; and sorted out the research findings of microstructure and defect in-situ real-time monitoring of metal laser additive manufacturing, and discussed the research trends for the next decade. Relevant findings were published in Reviews of Modern Physics (94,045002(2022)), and Chinese Science Bulletin (67, 3036-3053 (2022)). Zhao Cang thus won the 2022 IAAM Young Scientist Medal.

Teaching Achievements

The institute offers courses and comprehensive thesis training and guidance for undergraduates in mechanical engineering, as well as training for doctoral and master's students.

In 2013, the Exploration of Innovative and Practical Undergraduate Education in Mechanical Engineering and Automation completed by faculty members of the institute won the first prize of Beijing Higher Education Teaching Achievement Award.

In 2018, Dr. Zeng Jinle, supervised by Professor Du Dong, won the IIW Henry Granjon Prize - Category A.

The researcher team led by Academician Pan Jiluan of Tsinghua University worked with Shanghai Electric Group to complete the development of such technologies as low-voltage welded rotors for China's first million-level ultra-supercritical thermal power unit (in 2010), dissimilar steel rotors for China's first million-level 620 °C ultra-supercritical unit (in 2015), low-voltage welding rotors for China's first million-level independent nuclear power unit Hualong One (in 2017), and low-voltage welding experimental rotors for China's first 1905mm long blade nuclear power unit (in 2015); and cooperated with China Nuclear Industry Huaxing Construction Co., Ltd. to develop the intelligent welding technology and equipment for nuclear constructions, realizing the replacement of nuclear-grade welders, and meeting the welding standards of nuclear-grade equipment, which has been put into application in the automated welding of nuclear power components, such as containment steel linings, domes, and stainless steel pools in 10-plus nuclear power plant projects.