Introduction

The Institute of Mechatronic Engineering was established on August 30, 2013 by the new Department of Mechanical Engineering with the purpose of catering to the development of the Mechanical Engineering discipline of Tsinghua University and promoting the development of the secondary discipline of Mechatronic Engineering. The institute currently consists of three researcher teams for IC Equipment, Robotics, and CNC respectively, staffed with 20 faculty members. The IC Equipment team was titled Innovation Team in Key Fields by the Ministry of Science and Technology. Professor Zhu Yu serves as the deputy leader of the Expert Group of the 02 National Science and Technology Major Project, also known as the Project of Manufacturing Technology and Complete Sets of Technology for Very Large Scale Integrated Circuits.

Teaching Achievements and Talent Cultivation

The Institute of Mechatronic Engineering is committed to the cultivation of outstanding talents for mechatronic engineering by equipping them with solid basic theories and the ability to solve practical problems in engineering. Fruitful achievements have been made in teaching over the recent years, including one first prize of Beijing Municipal Education Teaching Achievement Award (Higher Education), one first prize of Teaching Achievement Award of Tsinghua University, two first prizes of the Youth Teacher Competition in Tsinghua University, one first prize of the Experimental Technology Achievement Award of Tsinghua University, and one Beijing Municipal Premium Textbook for Higher Education. The institute guided students to compete in the China Robot Competition and RoboCup Open, to have won a total of 6 championships. In addition, many teachers were awarded the Annual Excellent Teaching Awards, the Outstanding Class Teachers, and the Excellent Teachers for Graduates in Tsinghua University. The System Dynamics and Control course by Hu Chuxiong was selected as one of the first National First-class Undergraduate Courses in 2020. Many students have won special scholarships from Tsinghua University.

Discipline Orientation

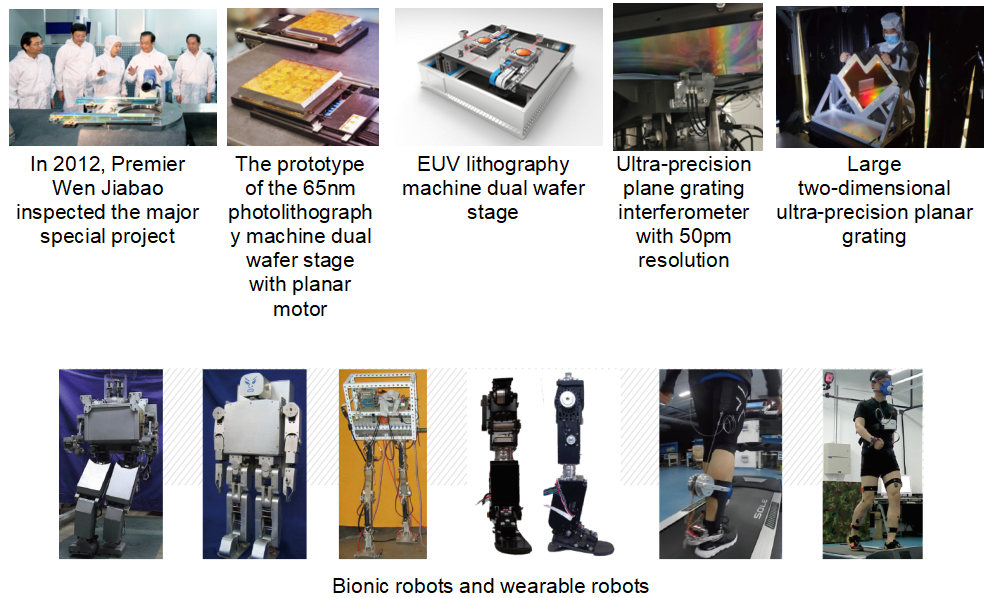

The Institute of Mechatronic Engineering has three disciplines: IC Manufacturing Equipment and Ultra-precision Measurement and Control, Robotics and Automation Technology and Equipment, and Advanced CNC Technology and Intelligent Systems, and offers courses and conducts researches on ultra-precision dynamics systems and control, nano-precision engineering and measurement and control technology, precision electromechanical systems of IC manufacturing equipment, robotics and bionics, special robotic technology and applications, digitalization and automation of aviation manufacturing, electromechanical CNC technology and applications, fluid transmission and control, etc. It has established several teaching and research bases, including the Research Center for Precision Machinery and Measurement and Control Engineering of IC Equipment, the Laboratory of Robotics and Automation, the Laboratory of Aerospace Automation Technology, and the Laboratory of CNC Technology. Its teaching and research facilities include industrial robots, nano-level ultra-precision workbenches, and sub-micron precision three-dimensional measuring machines, sub-nanometer resolution dual-frequency laser interferometers, and a 500-square-meter ultra-clean workshop, which provide strong support for high-level teaching and researches.

Research Achievements

The Institute of Mechatronic Engineering plays an important role in the China's mainstream industries, such as Xtreme manufacturing equipment, and aerospace. It has completed over 70 national and corporate scientific research projects, and won three national and provincial/ministerial awards, and one Military Science and Technology Progress Award. It has applied for over 150 Chinese and foreign invention patents, and published four academic monographs and nearly 400 papers, recording annual scientific research funds of more than RMB 50 million yuan on average. In 2005, the institute independently developed China's first 10nm precision synchronous motion test bench. In 2011, it developed China's first exchangeable lithography machine dual wafer stage. In 2015, it achieved a motion precision of 2nm. In 2012, meeting the national major demands in aerospace, the institute developed the first large-scale ultra-long 14-DoF redundant robot system for special pipeline spraying up to internationally advanced standards. In 2013, it successfully developed the world's first superconducting system for suspension drive of machine tool moving parts. With the above achievements, the institute has made outstanding contributions to the national scientific and technological innovation and development.