I. Main Experiments:

The laboratory is dedicated to experimental teaching in fundamental aspects of manufacturing, covering tools, fixtures, surface quality, and the measurement of dimensions, shapes, and positions. Additionally, comprehensive practices are carried out using various manufacturing equipment. The main experiments include:

1. Demonstrative introduction of advanced tools and machine tools.

2. Basic experiments focusing on processing quality, including tools, fixtures, processing parameters, measurement equipment and methods, along with various advanced manufacturing processing equipment and technologies.

3. Comprehensive experiments involving advanced manufacturing equipment.

II. Major Equipment:

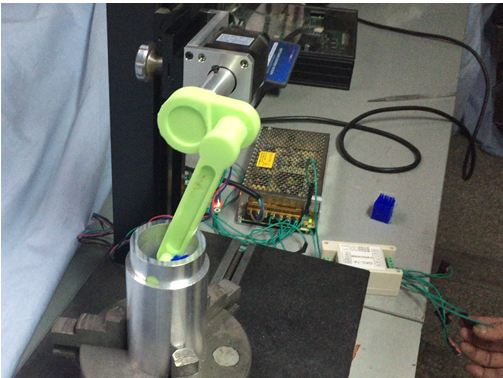

Small-scale general parallel equipment; Coordinate Measuring Machines (CMMs); numerical control mechanical innovation design experimental platforms; reconfigurable parallel configuration experimental platforms.

Tools

Tool angle measurement Fixture design and assembly Machining parameters

Turning experiment

Ultra-precision multi-axis numerical control machining

Small hole electrical discharge machining (EDM)

Parallel equipment machining

3D printer machining

Testing after piston group design and machining

III. Main Courses Supported:

Fundamentals of Manufacturing Engineering (National Quality Course), Fundamentals of Manufacturing Engineering A, Interchangeability and Technical Measurement, Information Technology in Manufacturing Engineering, Parallel Robots: Reconfiguration and Control Practice, Comprehensive Practice in Manufacturing Engineering, Digital Control Technology, Nontraditional Machining, Introduction to Micro and Nano Manufacturing, etc. In total, the laboratory accommodates over 500 participants annually, equivalent to about 4,000 student hours.

IV. Location and Directors:

Location: Room A417-2, Room A417-3, Lee Shau Kee Science and Technology Building (Open on workdays for university members)

Laboratory Director: Feng Pingfa. Deputy Laboratory Director: Kang Shanshan.