Driven by the rapid development of high-tech fields such as information technology, aviation, and aerospace, high-performance thin film materials play a key role in sensors, solar cells, microelectronic devices, and other fields due to their unique physical and chemical properties. During the thin film growth process, surface temperature is a critical parameter that directly affects the growth mode, deposition rate, and final quality of the film. However, existing substrate temperature measurement methods have limitations, such as low spatial resolution and large measurement errors, making it difficult to accurately reflect the true temperature conditions of the thin film growth surface. Moreover, the significant temperature gradient between the growth surface and substrate indicates that the substrate temperature cannot fully represent the true situation of thin film growth. Therefore, it is especially important to develop new technologies capable of accurately measuring the transient temperature on the thin film growth surface. This not only helps improve the quality of the thin film but also deepens our understanding of the dynamics of thin film growth.

The research group of Academician Wang Yuming and Associate Researcher Wang Zixi from the Department of Mechanical Engineering at Tsinghua University, in collaboration with the research group of Professor Ding Wanyu from Dalian Jiaotong University, used NiCr/NiSi thin film thermocouples to measure and analyze the surface temperature gradient during magnetron sputtering thin film growth. This work fills a gap in existing technologies and lays the foundation for subsequent mechanistic studies and application development. The related results were published as the cover paper in the top journal Small, titled "Measurement and analysis of surface temperature gradients on magnetron sputtered thin film growth studied using NiCr/NiSi thin film thermocouples."

Fig. 1. The cover paper of Small, titled “Measurement and analysis of surface temperature gradients on magnetron sputtered thin film growth studied using NiCr/NiSi thin film thermocouples”

This study, through the design and application of NiCr/NiSi thin film thermocouples, established a new measurement system to accurately capture the subtle changes in surface temperature during thin film growth. This system helps optimize the thin film preparation process, improve film performance, and provides important scientific evidence and technical support for the development of thin film technology.

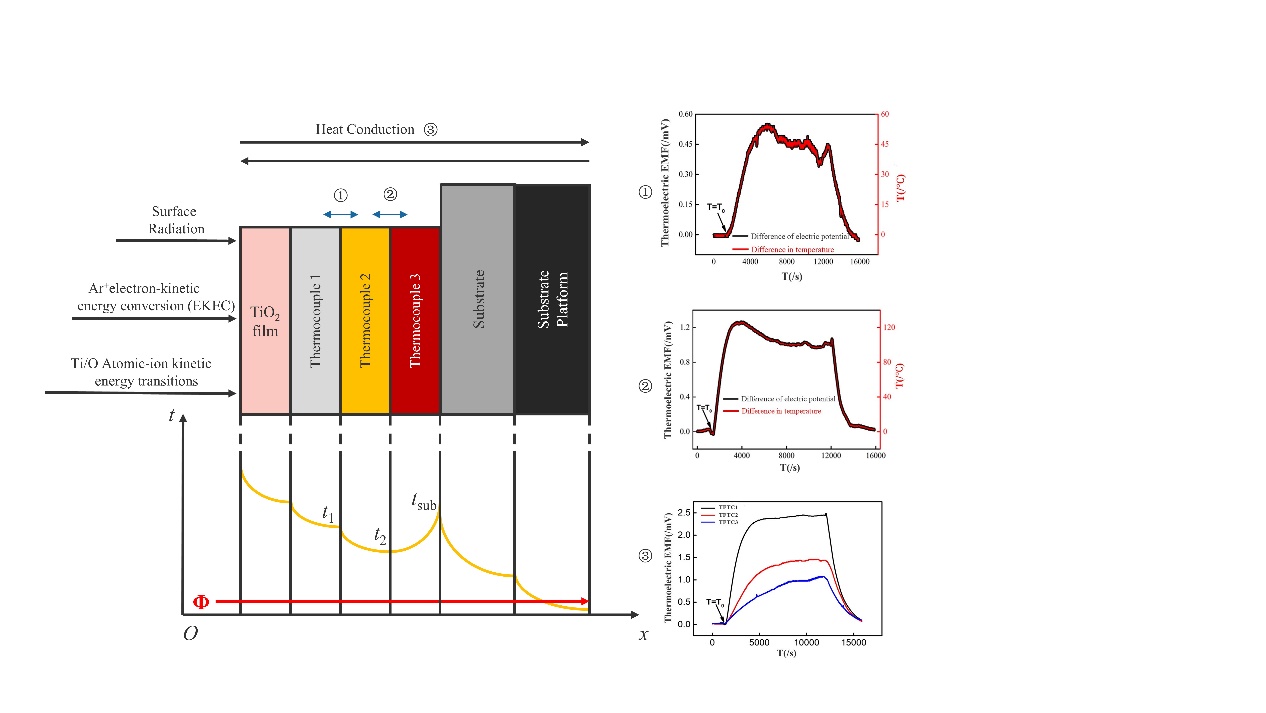

A 100 μm ultra-thin glass substrate was selected for the designed NiCr/NiSi thin film thermocouple structure, and a three-layer NiCr/NiSi thin film thermocouple temperature measurement system was fabricated to measure the surface temperature gradient during TiO2 thin film growth. Additionally, TiO2 thin films were deposited under a sputtering power density of 0.83 W/cm⟡, and the temperatures of the growth surface and substrate were measured. The results show that when the system reaches stability, the temperature difference between the first and second layers is 104.79 ℃, and the temperature difference between the second and third layers is 39.92 ℃. These results are consistent with the model and follow the basic laws of heat conduction.

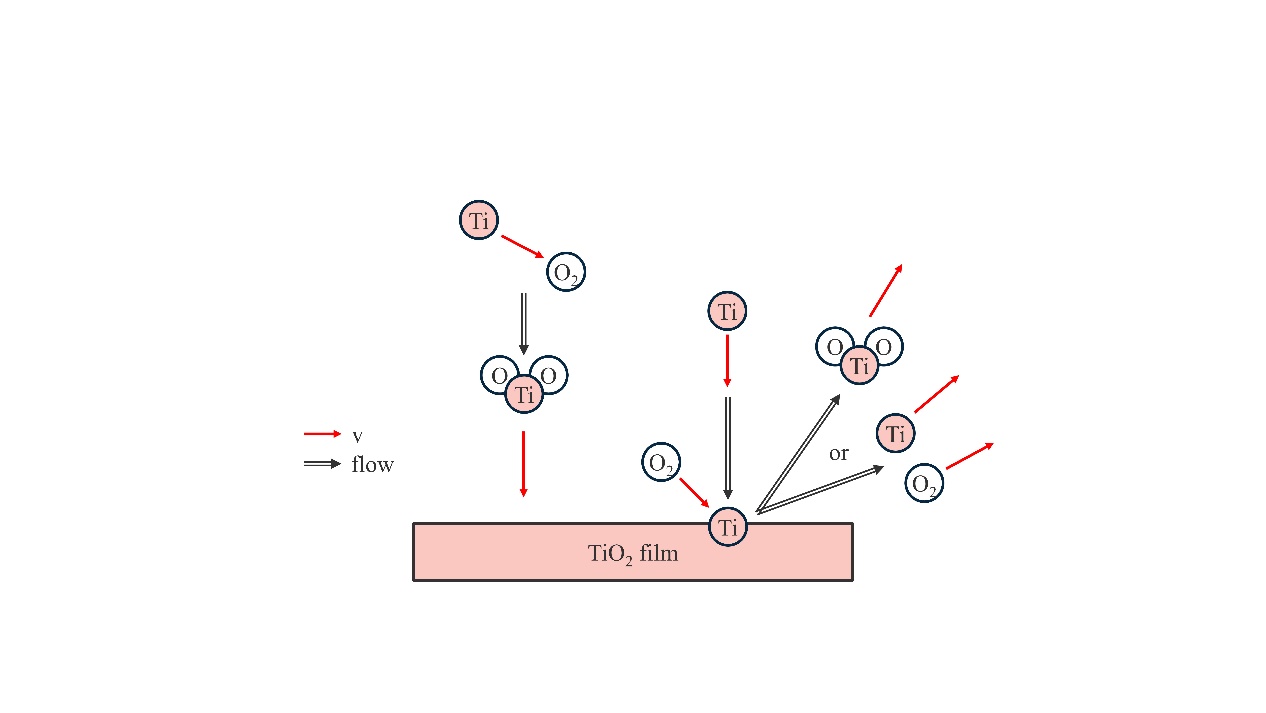

Fig. 2. Microscopic Mechanism of TiO2 Film Formation on Surface

In the TiO2 thin film deposition process, magnetron sputtering technology is used to fabricate the thin films. By evacuating the vacuum chamber to a low pressure and injecting Ar gas, Ar atoms are ionized into Ar⁺ ions and free electrons under the voltage applied to the electrodes. The electrons rapidly move to the glass substrate, while the positively charged Ar⁺ ions are accelerated and collide with the target (Ti target). These high-speed collisions provide sufficient energy for Ti atoms, causing them to be ejected from the target and react with O2 in the chamber to form the TiO2 thin film. During this process, electrons undergo numerous collisions with gas molecules per second, resulting in significant energy transfer. This model is important for understanding the interactions between electrons, ions, and materials, as well as the energy transfer mechanisms during the film formation process.

Fig. 3. Temperature Field Distribution and Experimental Results

The surface temperature of the TiO2 thin film growth and the substrate temperature were measured using NiCr/NiSi thin films and standard K-type surface-mount thermocouples. During the TiO2 thin film deposition process, thermal energy is primarily absorbed by the film growth surface. A significant temperature gradient exists from the film growth surface to the substrate. The temperature of the film growth surface is significantly higher than the substrate temperature. Considering the temperature of the TiO2 film growth surface, the temperature of the growth surface plays a key role.

Associate Researcher Wang Zixi from the Department of Mechanical Engineering at Tsinghua University and Professor Ding Wanyu from Dalian Jiaotong University are the corresponding authors of this paper. Dr. Liu Zhihui, a postdoctoral researcher from the Department of Mechanical Engineering, is the first author of the paper. This research was funded by the National Key R&D Program, the National Natural Science Foundation, the National Postdoctoral Fund, and supported by the National Key Laboratory of Advanced Equipment Interface Science and Technology at Tsinghua University.

Article link: https://doi.org/10.1002/smll.202404829