Recently, the Intelligent & Biomimetic Machinery Lab in the Department of Mechanical Engineering has made significant strides in the high-voltage applications of triboelectric nanogenerators, a breakthrough with far-reaching implications for electrostatic adsorption technology.

Electrostatic adsorption (EA), as an electrically controllable adsorption technology, has been widely studied and applied in active adsorption clamping and robotics. By applying a high voltage (~kV) to the conductor electrode, the technology can generate an electrostatic adsorption force between the electrode and the adsorbed object through electrostatic induction and polarization mechanisms. This process facilitates the adsorption effect or object grasping. However, the effective adsorption demands a reliable and stable power supply for the electrostatic adsorption system. Traditional commercial high-voltage power supplies tend to be bulky, which not only increases the system’s space occupation but also adds to its complexity and manufacturing costs. Consequently, the quest for a safe, reliable, efficient, environmentally friendly, lightweight, and portable advanced power supply solution for EA technology is a crucial challenge that must be overcome to promote the broader embrace of EA technology.

The lab has developed an innovative system utilizing a rotary freestanding triboelectric nanogenerator (RF-TENG) to power a multi-layer flexible thin film electrostatic adsorption damper (EAD). This system operates through a rectifier unit, ensuring a continuous and stable power supply. The flexible film electrostatic adsorption technology, which is based on triboelectric high-voltage, not only achieves self-sufficiency in energy supply but also demonstrates advantages such as lightness, safety, portability, and ease of operation. These attributes present a novel approach for the advancement of electrostatic adsorption technology and the application of high-voltage triboelectric nanogenerators in the future. This study has been published in the journal Advanced Functional Materials (AFM) under the title "Thin Film Electrostatic Adsorption Damper Based on Triboelectric High-Voltage."

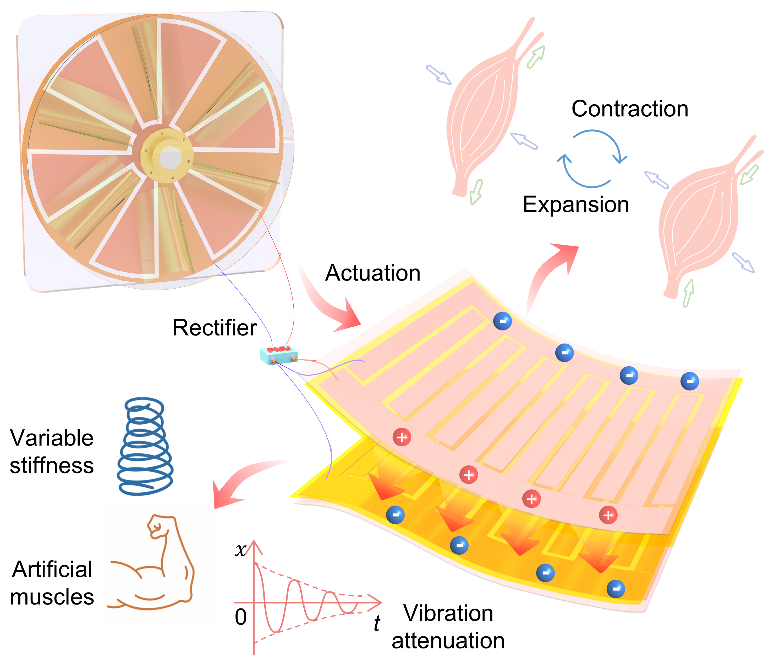

Fig. 1 Multi-layer flexible film self-powered electrostatic adsorption system

Drawing inspiration from nature, specifically the contraction and relaxation mechanisms of muscles, this research applies triboelectric high-voltage to the conductive electrodes of the EAD. This application hardens the film's structure, achieving a variable stiffness effect similar to that of artificial muscles.

The multi-layer flexible thin film self-powered electrostatic adsorption system consisting of rotary freestanding TENG (RF-TENG), rectifier and electrostatic adsorption damper (EAD). In this system, thin film EAD consists of two identical parts that generate electrostatic adsorption (EA) force when powered by RF-TENG. This EA force is produced through electrostatic induction and the mutual attraction of dissimilar charges, and it finds applications in artificial muscles, vibration attenuation, and variable stiffness.

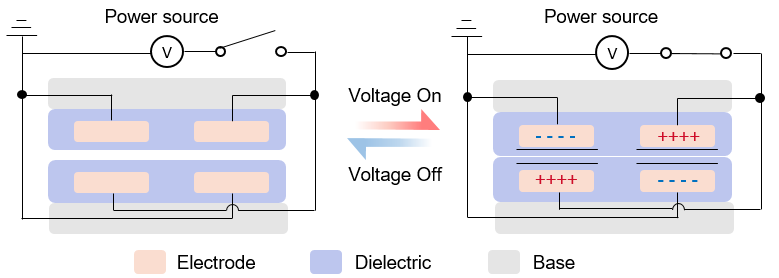

Fig. 2 Mechanism of electrostatic adsorption in EAD

The RF-TENG is composed of a stator and a rotor. The stator features a rectangular acrylic plate, which is equipped with two layers of copper foil electrodes covered with nylon film. In contrast, the rotor consists of a round acrylic plate and six fan-shaped polyvinyl chloride (PVC) films. The EAD is constructed from two symmetrical parts, each made from identical materials and structures. Specifically, a comb copper foil conductive layer is applied to a polyethylene terephthalate (PET) substrate using screen printing technology. This conductive layer is then covered with a polyimide (PI) dielectric layer, forming one part of the device. The two identical parts are subsequently combined to complete the EAD.

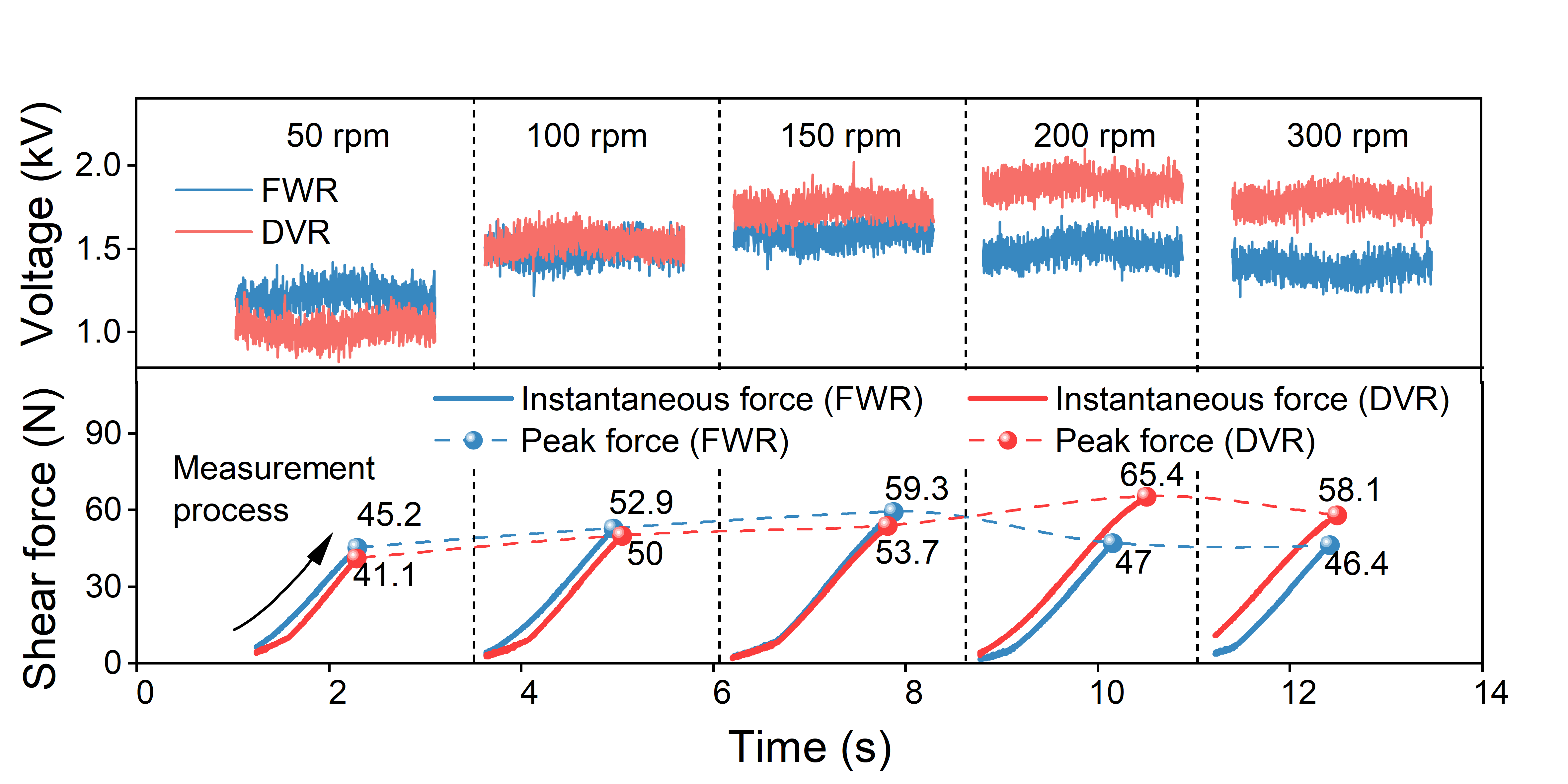

Fig. 3 The load voltage with EAD of RF-TENG and the shear force of EAD under FWR and DVR

The core of this technology is the ability to directly change the static and dynamic adsorption performance of EAD by adjusting the driving voltage, which is linearly related to the electrostatic adsorption force. This allows for precise regulation of its equivalent damping coefficient.

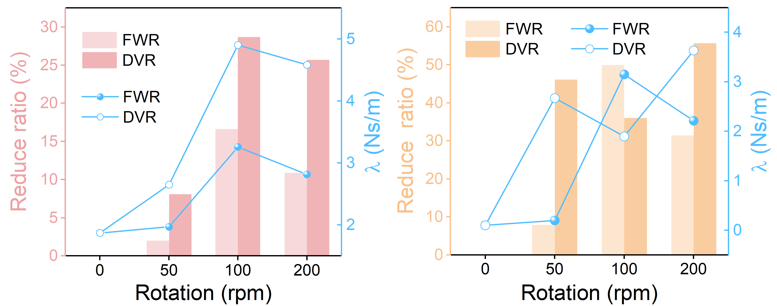

Fig. 4 EAD dynamic adsorption performance and equivalent damping coefficient λ based on RF-TENG

A one-dimensional mass-spring-EAD vibration system was established to investigate the dynamic adsorption properties and equivalent damping of the EAD through observations of both step response and sinusoidal response characteristics of the system. The equivalent damping coefficient could be adjusted from 0.1 N s m-1 to 5 N s m-1 at different RF-TENG rotation speeds, indicating that the equivalent damping can be accurately regulated by changing the output voltage.

This research was a collaborative effort led by Associate Professor Cheng Jia and Postdoctoral Fellow Yang Ze from the Department of Mechanics at Tsinghua University, with the first author being Master's student Lai Zhemin. This research was supported by the State Key Laboratory of Tribology in Advanced Equipment at Tsinghua University and funded by the National Natural Science Foundation project and the National Key Research and Development Program.

https://doi.org/10.1002/adfm.202412984