Recently, the Department of Mechanical Engineering of Tsinghua University has made significant progress in the field of micro/nano manufacturing based on colloidal self-assembly. The related article was published in the journal Langmuir under the title of "Analysis of the pattern shapes observed by micro/nano-spherical lens photolithography" and was selected as a supplementary cover in the journal.

Figure 1 The cover of the journal

● Background

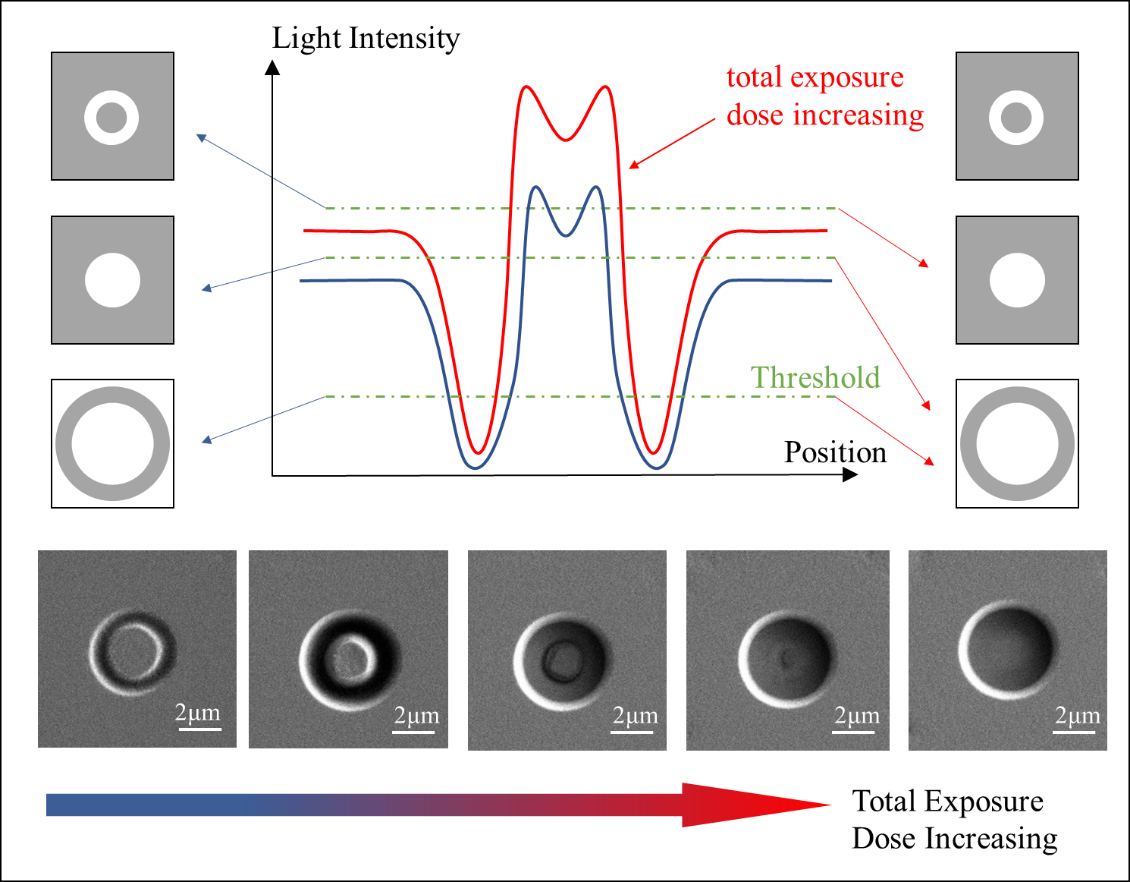

Micro/nano-spherical lens photolithography (SLPL) technology is a micro/nano processing method that replaces masks with self-assembled microsphere films on the basis of traditional lithography, utilizing the near-field optical effects of microspheres to achieve sub-wavelength scale features. Compared with traditional mask lithography methods, it has the advantages of high cost-effectiveness, easy implementation, high throughput and high precision. However, SLPL technology was previously mainly used to generate simple pattern shapes, such as circular arrays. Although many literature have shown that complex patterns can be produced with one single exposure, there has been a lack of systematic theoretical analysis, especially for predicting various non-circular shapes. At the same time, the numerical simulation of microsphere lithography technology faces the problem of complicated conditions and is hard to analysis, making it difficult to directly draw guiding conclusions from the simulation results. The picture shows the changes that occur when the exposure dose increases with the same microsphere. The curve in the figure represents the light intensity distribution curve after light passes through the microspheres, with blue line corresponding to low exposure intensity and red line corresponding to high exposure intensity. The green dotted line represents the development threshold of the photoresist (determined by the photoresist parameters). Different photoresist thresholds under the same light intensity curve will produce different patterns, as shown by the vertical patterns on both sides. Similarly, for the same photoresist threshold, increasing the exposure dose can also produce different shapes. The electron microscope images at the bottom correspond to the top green dotted line (photoresist threshold). As the exposure gradually increases, the patterns show the transition from a circular ring to a circular hole.

Figure 2 Schematic diagram of general conclusions for SLPL process

● Conclusions

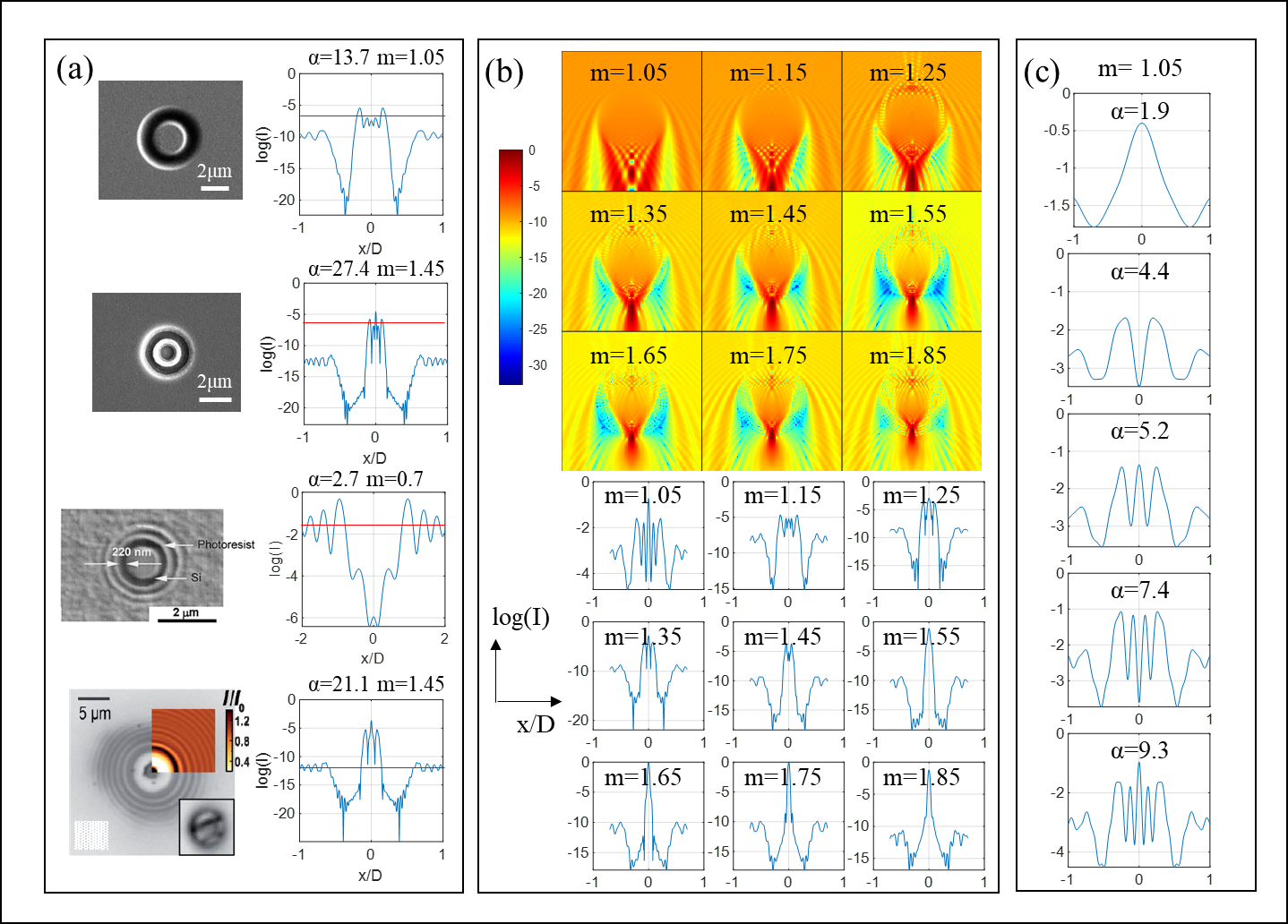

To address the issues above, our research group successfully prepared circular and non-circular pattern shapes based on the tension gradient induced rapid and large-scale self-assembly method of nanoparticles, using a densely arranged ordered colloidal particle self-assembly structure as a template instead of traditional complex nanolithography methods. Mie Theory was applied to systematically analyze and summarize various patterns that can be obtained through SLPL technology. This theory is conducive to using relatively intuitive analytical solutions to calculate, predict, and optimize the results of SLPL process, and analyze the physical laws of various influencing factors. The pattern shapes obtained are mainly controlled by two variables, namely the normalized diameter (the ratio of microsphere diameter to exposure wavelength) and the normalized refractive index (the ratio of microsphere refractive index to medium refractive index). Most non-circular patterns obtained in previous literature can be directly predicted using this simplified model.

After passing through the microspheres, the light intensity distribution on the tangent plane of the microspheres can be mainly divided into three regions. Among them, the peak region has the ability to produce sub-wavelength microstructures, which is the most noteworthy part. In order to obtain diverse shapes in this region, a lower normalized refractive index is the most critical factor. When the normalized diameter increases, the number of peaks in the central peak area also increases. However, an excessively large size can result in major errors between theory and experiment, typically making it difficult to obtain multiple concentric ring structures.

Figure 3 Experimental results and theoretical predictions

Based on this theory, we obtained single-ring and ring-with-hole structures, expanding the application scope of SLPL technology. Furthermore, using a simplified model by Mie theory, we have carried out a relatively comprehensive combing and prediction of the various possible patterns, further refining the theoretical basis of SLPL technology. These findings contribute towards promoting wider applications of SLPL in scientific research and industry in the future.

Guoxu Yu, a Ph.D. student from the Department of Mechanical Engineering at Tsinghua University, class of 2022, is the first author of the paper. Professor Jiadao Wang and Assistant Professor Yuan Ma from the Department of Mechanical Engineering are the co-corresponding authors of the paper. Postdoctoral Bowen Yu from the Department of Mechanical Engineering, Ph.D. students Yiqing Chen, Zhenwei Liang, and Xuanhe Zhang, have contributed to this work. This work was supported by the National Natural Science Foundation of China (NSFC).

Link for the article:https://doi.org/10.1021/acs.langmuir.3c01643